Antler / Horn / Bone End-mills (MH2I8) - (0.125" shank)

Overview

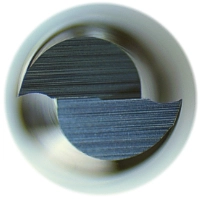

Think & Tinker, 2-flute, 1/8 inch shank Antler/Horn cutters are specifically designed to machine hard organic materials like antler, horn, bone and fossil ivory. The relatively large flute volume is designed to accommodate the sticky swarf that is often encountered with these materials.

Manufactured in the USA, every tool is:

- 100% measured / optically inspected to insure that EVERY tool meets, or exceeds, our published specifications

- made from premium grade submicrograin tungsten carbide (HRa 92, HRc 80)

This attention to detail and the use of top quality materials result in tools with dependable cutting characteristics and one of the longest tool lives in the market. Combined with comprehensive customer support, our cutters have become the tools of choice for sign makers, model makers, artists and instrument builders around the world.

NOTE: When cutting dense, brittle materials like fossil ivory, the TIR measured at 0.8in. (20mm) from the face of your 1/8in. collet MUST be less than 0.0007in. (0.018mm).

Specifications

- Geometry - 2 flute, 1/8in. (3.18 mm) shank, fish-tail tip

- Length - 1.5in. ±0.010 in.

- Diameter -

nominal ±0.0005 in. - Max runout (TIR) - < 0.0005 in.

- Max. depth of cut - EFL varies by diameter ±0.005 in.

- Anticipated Life - depends on material being cut (min 2,000 in.)

- Material - solid submicrograin carbide

- Ring Set - 0.800 in. ±0.002 in. (optional)

- Operating RPM - CNC certified operation 20k RPM to 100k RPM

Benefits

- Fish tail point eliminates backside breakout and splintering

- High flute volume supports high feed rates / chip loads

- Cutting edge geometry tuned to all aspects of inlay pocket cutting and component shaping

Applications

- cutting inlay and intarsia components from antler, horn, tusk, phenolic, and stabilized mineral products.

- pocket cutting in ebony, rosewood, and purpleheart

- engraving horn, tusk, antler, hardwood and phenolics

- slotting printed circuit board substrates

- machining thermoplastics for engineering and medical applications

Tutorials

- Getting ready to work with microtools for the first time

- Selecting the best tool for the material you are cutting

- Minimizing system runout with proper spindle maintenance

- Creating zero glue-line inlay

| Diameter | LOC | Flutes | Coating | Shank | OAL | Depth Rings | Reviews | Part Number | Price | |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0313" (0.79mm) | 0.150" (3.81mm) | 2 | 1/8" | 1.50" (38.1mm) | Available | MH2I8-0313-015F |

$10.87 |

0.0313" (0.79mm) | 0.150" (3.81mm) | 2 | ZrN | 1/8" | 1.50" (38.1mm) | Available | MH2I8-0313-015FC |

$15.40 |