Channel Cutting in Phenolic Counterplates

Phenolic Counterplates

First introduced in the 1980s (Rilma counterplates), phenolic counterplates marked a major improvement in press make-ready over hand-cut mats and hand placed Matrix. Fabricated from multiple sheets of paper, or linen, impregnated with phenolic resin and laminated together under high temperature and pressure, phenolic counters are dimensionally stable, water and solvent resistant, and able to be machined to tight tolerances. Comprising all the necessary crease channels and registration features to accommodate the associated steel rule die (SRD) into a single, unitary plate, counterplates afford greater flexibility in the complexity and density of pattern features making them a better choice for dies with a higher number of clones, repeat jobs, complex geometries and high-volume production runs.

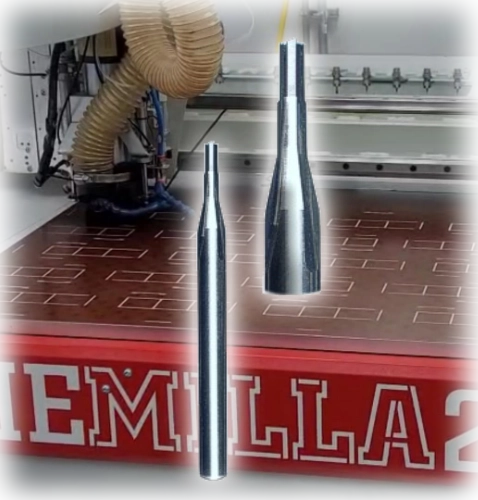

An added benefit is that the phenolic sheets can be machined on the same CNC milling machines that cut the wooden counterboards used to make the SRD, affording near perfect co-registration between the creasing channels and creasing rule in the die. The availability of modern specialty cutters makes it possible to optimize channel edges and profiles to virtually eliminate bruising of the substrate in the corners at the ends of the creases, a major consideration in the fabrication of packaging for luxury items.

Before you run the first piece of code and start making chips, there are a few basic practices you should employ to help you get off to a good start. These may seem a bit fiddly at first, but they will help you achieve more reliable cutting, higher feed rates, better cuts and fewer broken bits.

Preparing Your Spindle / Router

To get started:

-

Clean the spindle bore, collet and nut with ColletCare or a similar cleaner / lubricant ( COLLET CLEANING ). - It is essential that the collet seat into the spindle bore with minimal interference or resistance. Keeping this area clean, lubricated and free from debris will also help minimize runout (aka TIR , "The Bit Killer"). DO NOT lubricate the collet bore as this may cause the bit to slip under heavy load.

-

Periodically check the runout of the collet you are using (COLLET RUNOUT). - There are a lot of very good technical reasons why you need to minimize runout in your spindle (or router), but they all boil down to the fact that getting control of how much your bit is wobbling results in lower bit breakage, more precise cuts, better fitting inlays and reduced wear and tear on your spindle bearings. More will be said about the importance of measuring and correcting TIR in a later tutorial.

-

Use "air cuts" to check your code before committing to a cut (you don't even have to have a tool loaded). - Find problems with your tool path, clamp placement, mystery plunges or errant tool paths that land outside your part before you you actually cut anything.

-

Make sure the spindle turns ON when you start your code. - I know, this sounds obvious, if not a little silly but, sooner or later, we all make this mistake and it can be costly.

-

Make sure the spindle is rotating in the proper direction when it first spins up. - The vast majority of cutting tools that you will use will be right-hand-cutting (RHC) bits. That means that the spindle should be spinning CLOCKWISE as viewed from the top. An easy way to check this is to look at the spindle nut when the motor first starts turning. The side facing you should be rotating from RIGHT to LEFT.

-

Mount the nut and collet onto the spindle. - If you are using ER style collets, or our high precision router collets, make sure that the collet is properly snapped into the nut ( ER COLLETS) .

-

Load the cutter into the collet and tighten the nut to the recommended torque ( TORQUE TABLE).

Optimizing Chipload

Chipload is basically how big a bite one flute (or one tooth) on a rotary tool takes in a single revolution. Another way of thinking about it is that it is how far the tool moves forward in one revolution divided by the number of flutes (teeth).

If you multiply the chipload by the total number of flutes (or teeth), you get the "total chipload".

It is easily calculated by dividing the feed-rate by the RPM and then dividing the result by the number of flutes (or teeth) on the tool.

- CHIPLOAD = FEED-RATE / (RPM x #FLUTES)

A common strategy, when using a cutter in a new material is to try some test cuts (or get recommendations from the bit manufacturer) to find a combination that works well and use the above calculation to determine a working chipload for the material. If you have the time, you can vary the speed and feed to try to find an optimum combination, an optimum chipload. The real benefit of knowing the chipload is that it is basically a characteristic of the material and, as such, while dependent on the diameter of the cutting tool, is relatively independent of the speed, feed, or flute count. If you have the recommended chipload of a material wit a given cutting tool, you can use it to calculate a working combination of speed (RPM) and feed-rate for your machining operation, even if you are using a different diameter cutter.

Calculating Feed-rates

Before you can use the chipload to calculate the feeds and speeds for your CNC, you must have a firm understanding of what your machine is capable of. Characteristics of your machine that you should be familiar with (or know where to look up) include:

- Maximum RPM - This is the one parameter the manufacturer usually knows.

- Minimum RPM - How far can you turn down the rotational speed on your spindle and still have enough torque to cut the material you are machining? There is a lot of contrary information about this online. In most cases some simple testing can determine this number. For multiphase spindles (variable speed using a VFD), you can safely lower the RPM 50% from the maximum value before worrying about torque or power limitations.

- Maximum feed-rate - How fast can your CNC cut along each axis without losing position or distorting due to flexibility in the frame and/or gantry? (Goor luck getting this information from the manufacturer of your machine. Generally, it is more reliable if you measure these parameters experimentally doing test cuts at various feed-rates under different loads. We have some experience with this if you need help setting up some tests.)

- TIR - What is the runout (TIR of the spindle/tool holder/collet combination you are using? if you don't know, please take time to measure the runout!)

Information you need to know about your cutting tool and the material being cut.

- Tool diameter

- Number of flutes

- Flute length (depth of cut)

- Desired depth of cut - Some cutting tools will have a recommended maximum depth of cut (DOCmax) in the material you are machining. It is also important to make sure that your depth of cut is not significantly greater than the thickness of the material to minimize how much you cut into your spoil board.

- Manufacturer suggested chipload for the material you will be cutting. (unfortunately, this is rarely available, but it never hurts to call)

Assuming that you know all of the above, determining the RPM (S) and feed-rate (f) comes down to choosing one (S or F) and calculating the other.

NOTE: When cutting phenolic counterplate with solid carbide bits with diameters of 1/8 in. (3.18mm), or less, we recommend running the spindle as fast as it will go to develop enough shear to cleave the material cleanly.(assuming your machine has enough feed-rate to support this RPM).

For instance:

- If you specify the RPM (S):

- Feed-rate (F) = S x #Flutes x Chipload

- If you specify the Feed-rate (F) (this form is especially useful if you have a CNC with a low maximum feed-rate and need to lower the RPM to maintain chipload)

- RPM (S) = F / (#Flutes x Chipload)

Sample Calculations

Working with Jerry Gonzalez (Advanced Paper Box, Los Angeles, CA), we have determined that a working chipload for the brown Rilma Counterflex counterplate machined with our 0.060" diameter, 3-flute, zero-helix channel cutter is 0.00203 inches/flute/rev. We can use this value to calculate a working feed/speed combination for virtually any machine we want to use to machine this material, with this tool (assuming it is not a total piece of crap).

- Using the 060" dia., 3-flute cutter on a CNC with a spindle with a maximum speed (S) of 24,000 RPM and no worries about the feed-rate (F), we can calcualte:

- Feed-rate (F) = 24000 x 3 x 0.00203 = 146 inches per minute (IPM)

- If our CNC router tops out at 100 IPM, we can calculate a suitable RPM with:

- RPM (S) = 100 / (3 x 0.00203) = 16,420 RPM