V-tip Engraving Tools

V-tip Engraving Tool Specifics

Tool Geometry

Before diving into the calculations specific to V-tip tools, it would be a good idea to take a look at the geometry of a typical bit and discuss the advantages and limitations of this class of tools.

V-tip tools are commonly available in 1-flute, 2-flute, 3-flute and 4-flute configurations. You can also find "V" style bits with much higher flute counts but these typically fall into the category of "burrs" that are used in grinding operations.

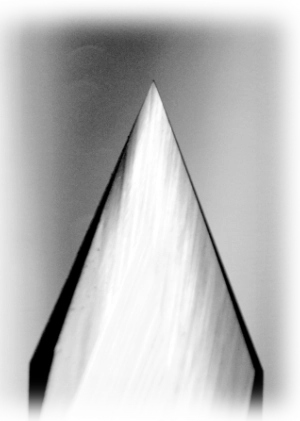

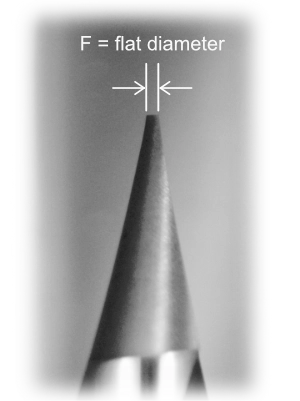

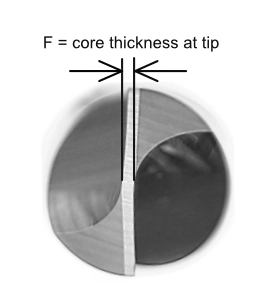

First, and foremost, no v-tip tool has "cutting geometry" all the way to the center of the tip. In other words, when a v-tip bit is fabricated, the closer you grind to the center of the blank, the harder it is to actually form cutting flutes. Also, the closer you get to the center, the weaker the material gets, until you get to the point where there is not enough strength left to actually engrave anything tougher than a marshmallow. The smaller the tip, the weaker it is. That is the primary reason that a properly designed v-tip engraver will always have a flat cutting tip, with the size of flat diameter ("F") being determined by how strong the tip needs to be for use in a specific application. As you can see from the images, from one direction the tip looks infinitesimly sharp but, rotated 90°, the flat tip that results from the thickness of the core, is plainly visible. One way to sum it up is to say "the thicker the core, the bigger the flat diameter, the stronger the tool". As in all rotary cutters, there is a tradeoff between the strength of the cutter and the smallest feature it will cut (resolution).

There are a few tools out on the market that show a very sharp tip at the end of the tool, but a close examination shows that the actual cutting edges stop short of the end and the tip is designed to push material out of the way, not cut it. This might be an acceptable strategy for soft woods but never for hardwoods, metals or plastics.

Applications

Note: V-tip tools are also very popular for enrgaving metals, mechanically etching printed circuit boards and deburring metal edges, but those applications are outside the scope of this article.

The tools we are concerned with here are specifically designed to scribe lines or cut chamfers in hardwoods and composites with very little deflection, even under heavy loads This characteristic makes tools in this class very useful for a variety of primary and secondary tasks including:

- in luthery applications, scribing a shallow groove into the fingerboard at each fret position creates a "guide" channel that helps reduce the deflection of the fret-slot cutter. If this guide channel is wider than the diameter of the slot cutter, a symmetric chamfer on either side of the slot is formed, removing the need to manually file the slots prior to fretwire insertion.

- in engraving operations, the tool geometry allows the width of the engraved line (or width of a chamfered edge) to be varied by varying the depth of plunge

- in woodworking, pre-chamfering dense and brittle hardwoods can eliminate top surface chipping by up-cut endmills, even at high chiploads, because the top edge of the material is pulled back from contact with the upward shear of the cutting flutes

- in cabinetry, pre-chamfering softer woods and plywoods can virtually eliminate the formation of hair and splinters that have to be removed, or repaired, before continued processing. In large, complex designs, like monograms or furntiure, this single step can save hours of sanding.

Calculating Plunge Depth

One of the complications that you encounter when using V-tip bits is determining how deep to plunge them to achieve specific line widths and what RPM and feedrate is suitable for the material you are cutting. To demonstrate the required calculations, we will consider how to pre-scribe channels in the fretboard of a stringed musical instrument prior to cutting fret-slots.

The following calculation are based on the use of a 60° V-tip bit belonging to our 2-flute Carbide Chamfering / Engraving Bits (EM2D8) tool family.

Preparing fret-slots for the insertion of fretwire normally involves symmetrically hand-filing chamfers on both sides of the slot with a 3-sided (60°) jewellers' file. Typical values for the chamfer width vary from 0.005" (0.127 mm) to 0.010" (0.254 mm).

In the example below, we will use a guide channel to form 0.005" (0.127 mm) chamfers on both sides of a 0.023" (0.584 mm) wide fret slot giving a total "V" width of 0.033" (0.838 mm)

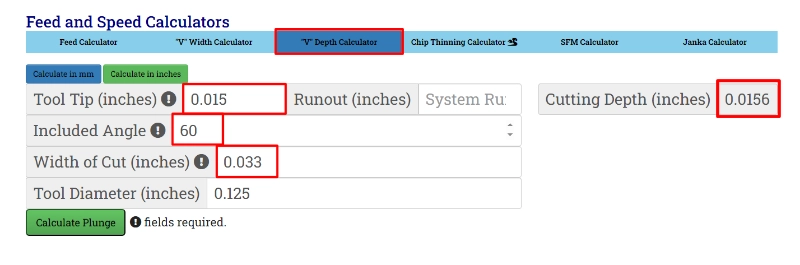

To calculate the plunge depth, use the V-Depth Calculator (included in the Feed and Speed Calculators at the bottom of any page of this website.

- Select the "V" Depth Calculator (middle of the blue banner)

- Enter:

-

- Tool Tip = 0.015 (flat-tip diameter from above)

- Runout = 0.00 (ignore for this example)

- Total Angle = 60

- Width of Cut = 0.033

- Tool Diameter = 0.1250 (max. dia of v-tip)

- Click on the green Calcluate Plunge button (lower left of caclulator)

- The calculated Cutting Depth (upper right corner) is 0.0156" (0.4 mm)

Calculating Feedrate

As with all rotary tools, the feedrate is dependent on the cutting diameter of the bit. When engraving a v-channel, the maximum width of the channel (distance between top edges) is used as the Tool Diameter.

As discussed in the "Rules of Thumb" section of First Steps for Machining Wood with Microtools, maximum rotary shear is achieved by running bits at the MAXIMUM RPM appropriate for the tool diameter.(For the sake of brevity, suffice it to say that you should run bits with cutting diameters less than 0.0125" (3.18 mm) as fast as you can.)

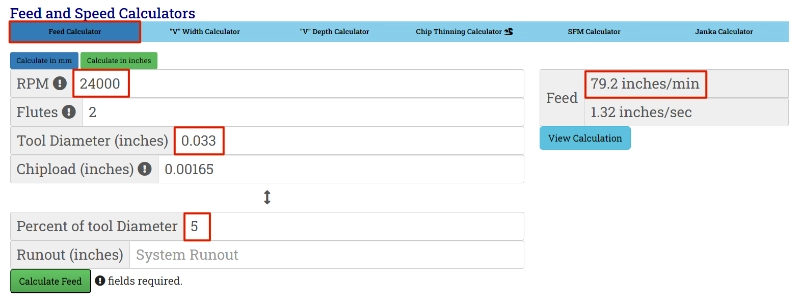

To calculate the feedrate, use the Feeds and Speeds Calculator(at the bottom of any page of this website).

- Select the Feeds and Speeds Calculator"

- Enter:

-

- RPM = 24000 (max. available on our system)

- Flutes = 2 (2-flute V-tip)

- Tool Diameter = 0.033 (calculated above)

- Chipload = (this will auto-calculate when you enter the percentage value below)

- Percent of tool diameter = 5 (safe value for this family of V-tip tools)

- Runout = 0.0 (ignore for this example)

- Click on the green Calcluate Feed button (lower left of caclulator)

- The calculated Feed (upper right corner) is about 79 inches/min (2,000 mm/min)